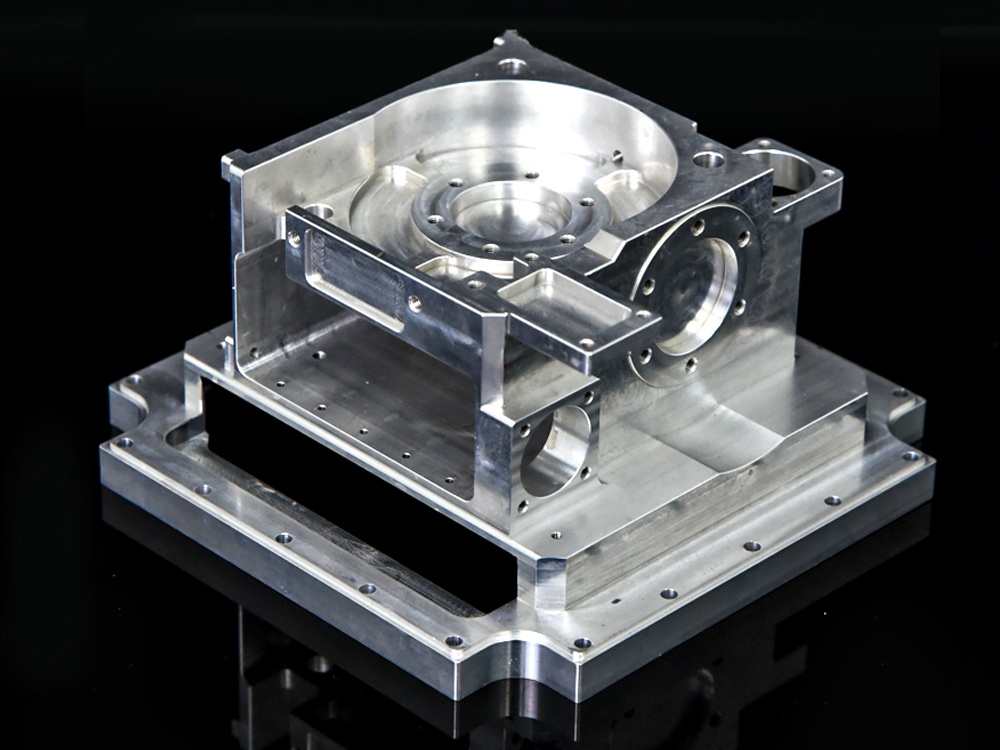

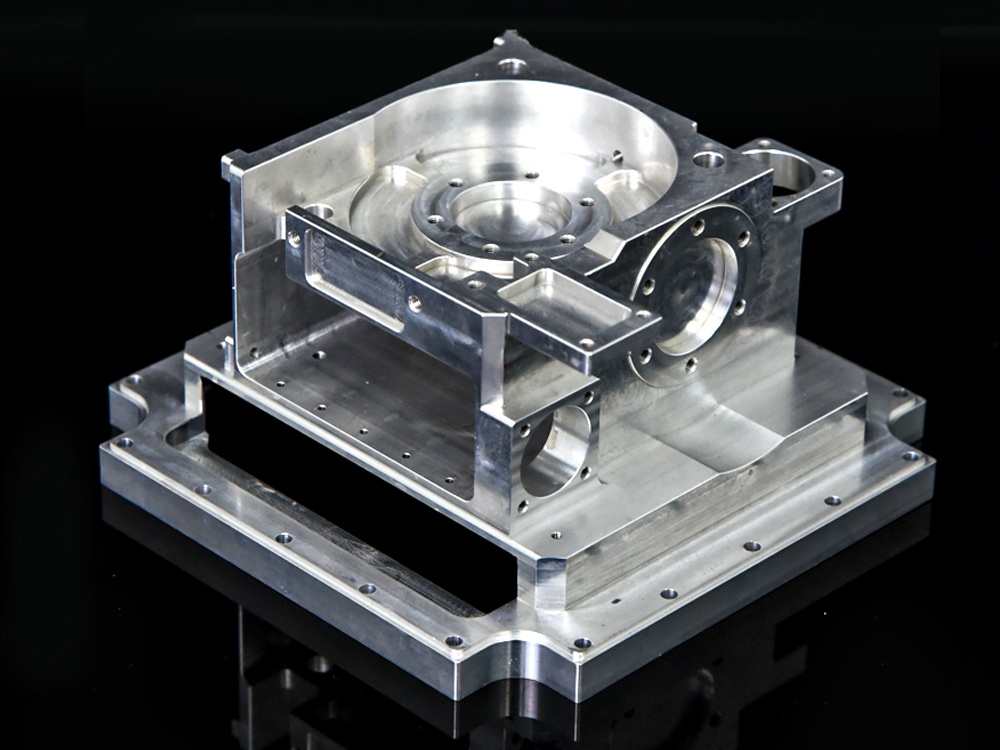

Precision Custom CNC Machining Manufacturer

Wolf Precision is a trusted CNC machining manufacturer that operates its own factories and collaborates with highly skilled professionals, delivering high-quality, customized metal parts with precision and reliability.

- Orders From 1 Pc To 10,000+ Pcs

- Professional Engineer Support

- Rapid Lead Times

- Starting From 3 Days

- Tight tolerances ±0.005mm, Ra 0.2μm finish

Manufacturing Capabilities

We provide comprehensive manufacturing solutions for both rapid prototyping and low-volume production, with expertise in producing geometrically intricate and high-quality cosmetic components.

CNC Machining

We provide comprehensive CNC milling and turning services, supplemented by EDM and grinding operations. Choose from over 100 materials and more than 60 surface finish options.

3D Printing

Competitive custom sheet metal fabrication services for low-volume prototypes and cost savings for high-volume production.

Injection Molding

Producing robust, cost-efficient parts with quick turnaround and adaptable workflows to meet varied industrial requirements.

Vacuum Casting

We provide comprehensive CNC milling and turning services, supplemented by EDM and grinding operations. Choose from over 100 materials and more than 60 surface finish options.

Sheet Metal

Competitive custom sheet metal fabrication services for low-volume prototypes and cost savings for high-volume production.

Die Casting

We provide comprehensive CNC milling and turning services, supplemented by EDM and grinding operations. Choose from over 100 materials and more than 60 surface finish options.

Stamping

Producing robust, cost-efficient parts with quick turnaround and adaptable workflows to meet varied industrial requirements.

Aluminum Extrution

We provide comprehensive CNC milling and turning services, supplemented by EDM and grinding operations. Choose from over 100 materials and more than 60 surface finish options.

Machining Hours/Month

How Wolf Precision Works

From quote to delivery, we streamline the entire process—delivering efficient, high-quality manufacturing solutions that simplify production and ensure reliability.

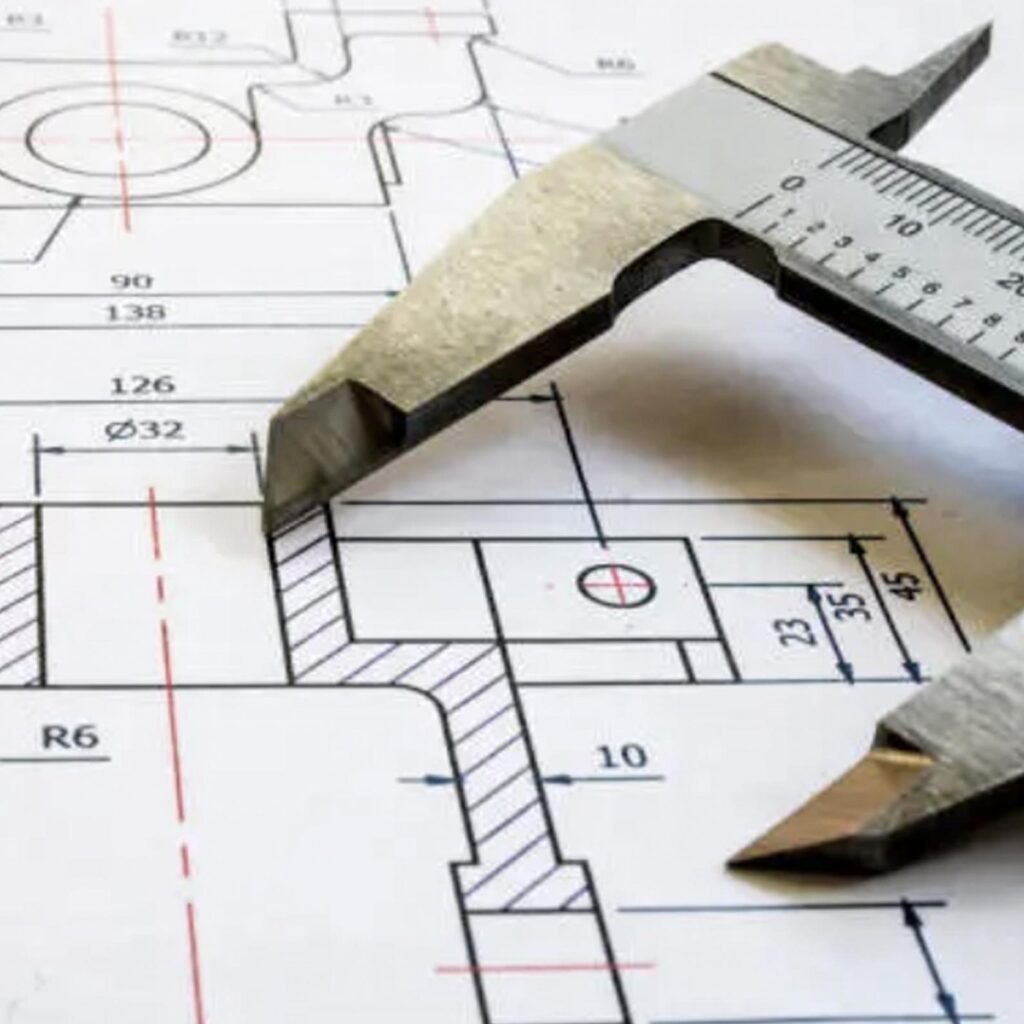

Uploading Drawing

Drawing Format

CAD files:

2D: DXF | DWG | PDF

3D: STP | STEP | IGS | IGES | X_T | SLDPRT

Drawing Confidentiality

Your information will only be used for quotation purposes

DFM Evaluation & Quote

Drawing Review

Ensure clear and reasonable dimensions, tolerances, and material specs.

Material & Process Evaluation

We optimize processes, solve challenges, and verify materials for cost and lead time.

Optimization & Cost Evaluation

We recommend design improvements, refine processes, and estimate costs to maximize savings.

Order Confirmtion & Production

Sample Production & Inspection

Produce samples as planned and verify quality through testing.

Drawing Confidentiality

Share visuals for approval, send samples, and adjust based on feedback.

Mass Production Planning

Finalize schedule, materials, and equipment after approval.

Quality Inspection & Delivery

Material & First Piece Inspection

Inspect raw materials and verify initial process settings before mass production.

In-Process & Final Inspection

Perform random checks during production and conduct final inspections to ensure quality.

Pre-Packaging Inspection

Check parts before packaging to guarantee safe transport.

quality control

1-Incoming Material Inspection

Inspect raw materials for appearance, dimensions, composition, and hardness compliance. Document test data for traceability.

2-In-process Inspection

Perform real-time dimensional and visual checks after each production step. Record data to ensure specification adherence.

3-First Article Inspection(FAI)

Validate the first completed unit against design drawings. Generate an FAI report documenting critical dimensions.

4-Final Product Inspection

Test finished products for appearance, dimensions, performance, and functionality. Issue a QA report certifying compliance with customer specs.

application

We are a professional manufacturer of CNC machined components. We manufacture precision metal parts that are generally used in different categories of industries including:

Automotive

Robotics

Energy

Medical Equipment

Aerospace

Optical Lens

Ask For A Quick Quote

Get instant pricing, project lead times,

and DFM feedback.

Join 6,400+ Companies Who Use Witcool For High Quality Parts

- Phone Number:

- Address:

Pre-Inquiry Checklist

- Quantity

- Material

- Heat Treatment (if necessary)

- Surface Finish (if necessary)

3D CAD files in STEP, IGS format; 2D files in PDF, or DWG format.

PDF drawings should include tolerances, critical dimensions and threaded holes.